Ripple Residence: Demonstrating commercial attractiveness of developing low-carbon residential projects in Copenhagen

For more than a decade, Urban Partners has taken a lead on integrating climate solutions as a central part of its business strategy. For real estate developments, it has meant taking on innovation as a corporate skillset, based on the projection that low-carbon development investments have a strong commercial case.

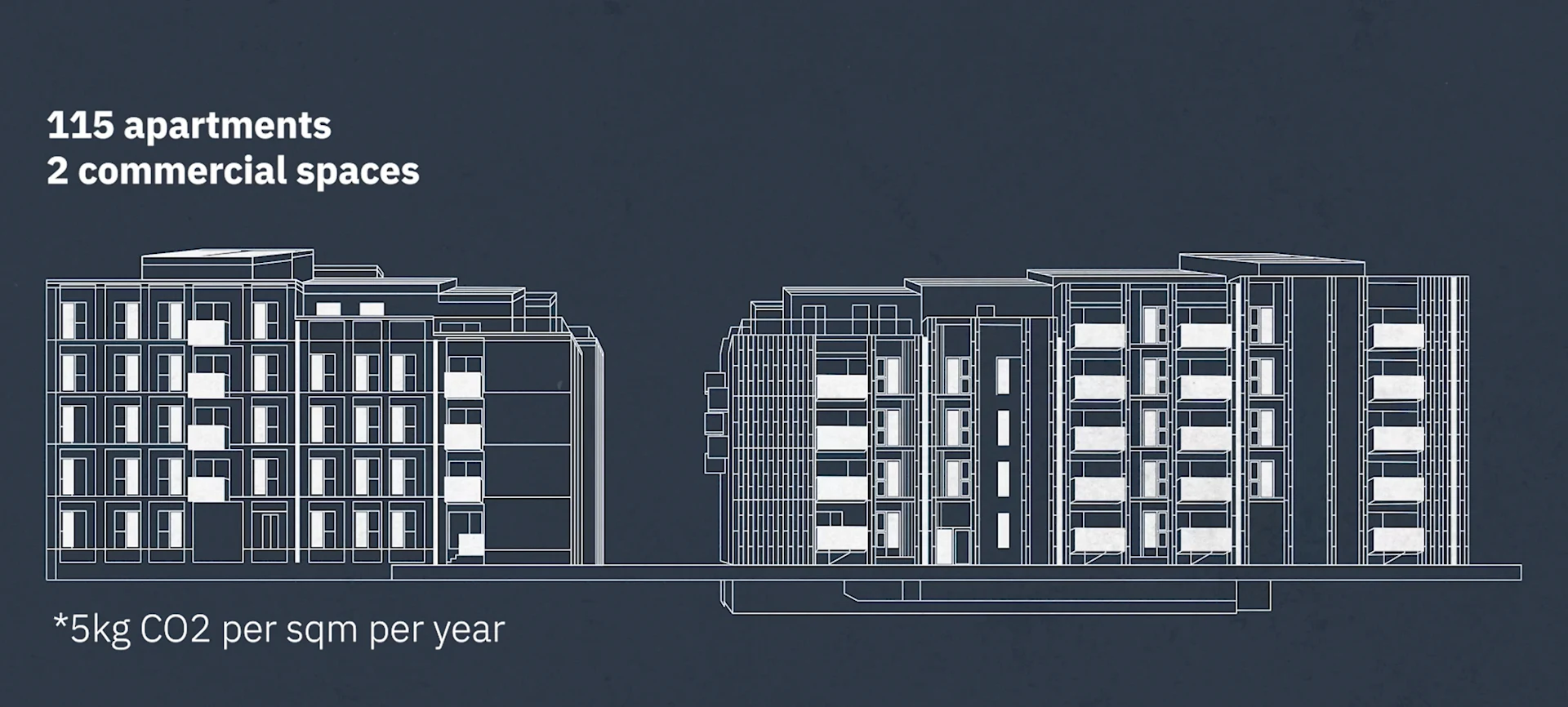

One example is Ripple Residence, a development by Urban Partners’ real estate investor Nrep in collaboration with Henning Larsen Architects, now taking shape in the Nordhavn neighborhood of Copenhagen. It takes insights from previous projects and pushes the boundaries of sustainable real estate.

The development is expected to have embodied emissions of 250kg CO2e per square meter (5 kg per year), and operational emissions of 1.1kg CO2e per square meter per year, both significantly lower than the current average of a Danish new residential multi-story building. With Danish regulations setting out increasingly tight requirements on whole life-cycle emissions, projects like Ripple Residence are paramount to informing Urban Partners’ understanding of how to commercially scale solutions for low-emission and energy-efficient residential development investments.

Innovation in action – upcycled materials, timber construction & clean energy systems

To drive carbon reduction innovation in a development project, the developer must be very close to the value chain players, bringing in the right contractors and main suppliers at a very early stage. It is critical to be involved in decision making from the very early stages to gauge new solutions and related risks with the latest knowledge on an ongoing basis – particularly in a sector that prefers to do business as usual and where innovation is typically not part of the standard procedures. Data-backed insights are an integral part of decisions taken on Ripple Residence, which allows for selection of energy solutions and building materials based on practical experience. Carefully screening and selecting the right partners from the start is key. Ripple Residence is based on strong collaboration with the contractor, 5E Byg, Søren Jensen and Henning Larsen Architects, who are all equally committed to exploring ambitious sustainability solutions.

Upcycled Materials

Resource Rows, an Urban Partners residential development in Copenhagen, was pioneering in terms of using upcycled materials. It also showed the challenges of doing this at scale and maintaining cost-competitiveness, and that recycled does not necessarily mean low carbon - highlighting the importance of leading with third-party life cycle assessments (LCA) from suppliers.

From Resource Rows, the team learned that working with upcycled materials was beneficial only if these were available and fit well in the new project – hence the usage on Ripple Residence was clearly targeted and for specific parts of the project. Otherwise, the risk becomes trying to use quantities that are more complicated to get hold of, or to adapt the design to fit what is available.

As a result, Ripple Residence uses upcycled materials but in smaller amounts, focusing on selecting the best materials in the market based on available data. For example, concrete and granite tiles were reused from a building being torn down elsewhere in the city, because they fitted well in the waste room. Kitchen equipment, in rust free steel, was reused from a production kitchen and fitted in the orangerie.

Timber Construction

Another one of the firm’s residential projects, UN17 Village, provided important learnings in terms of biobased materials. Building with wood instead of concrete, it showed the importance of implementing solutions for potential acoustic problems and adequate fire protection right from the start. These become much more complicated to solve in the later stages of a project.

The team took the learnings from a hybrid wood/concrete building at UN17 Village and considered how to replace even more of the concrete with wood in Ripple Residence. The result was a building made entirely from wood, other than the floors of the bathrooms and the basement at the ground level, without affecting structural integrity.

Another key lesson from UN17 Village’s use of wood is the importance of establishing a fire safety strategy from the start that ensures compliance with local regulations. Sprinklers had to be introduced during the design phase to meet ambitions for the project, which increased costs and affected the aesthetics. For Ripple Residence, it was a clear goal from the start to design the building without a sprinkling system, which is not suitable for a timber building.

All primary building parts were designed for prefabrication, modularity, and future disassembly or re-use. The bathrooms are prefabricated in a wooden construction from a known and trusted supplier and have the same guarantees as their concrete solution. Establishing this supply chain means that it will be much easier to employ this technique on future projects.

UN17 Village had shown that it is hard to work with wood in Denmark’s climate, because rain and damp affect the material and bad weather can slow or even prevent work for periods. For Ripple Residence, there is a SiteCover roof and shelter to keep things dry during construction. This comes at an upfront cost but decreases both the risk of costly delays and carbon emissions, as no work days are lost to bad weather and less energy is needed for drying out the wood.

Energy

An advanced energy system brings together geothermal heating, heat recovery and solar panels with a smart control system, making the building almost energy self-sufficient. Geothermal energy is relatively new in Danish residential projects, and so its deployment required close interaction and flexibility from both developer and supplier Energy Machines.

It comes at a higher upfront cost than a simple grid connection but its operational costs are a fraction of usual heating and cooling, generating a meaningful uplift for a future divestment valuation. This can also now be deployed on other projects.

The commercial reward for innovation – attractive financing terms & sales premiums

The sustainable nature of the project opened up multiple attractive financing options, and Urban Partners was able to secure favourable terms. This highlights that projects with a strong focus on decarbonization, when planned well, can attract financing that is both supportive of sustainability and beneficial for long-term profitability.

A second important element is that Nordhavn is one of the most sought-after areas in Copenhagen and the target residents are likely to be willing to pay a premium for extra quality and sustainability, as their operating expenses will be significantly lower. On top of this, buyers tend to prefer larger apartments than renters, and fewer apartments in the same building brings down costs as the technical requirements are simpler, with for example a smaller number of kitchens.

This was the basis of a decision to sell rather than rent the apartments. There appears to be significant demand, as registered interest to buy an apartment in Ripple Residence is high.

The construction costs are projected to be about 20% higher than a traditional project, and the result of the green financing and selling the apartments, on top of the more efficient construction, is that the commercial case is now just as strong as it would have been with a traditional building on the site.

The building will most likely remain standing for more than 100 years and it is highly probable that if the building were demolished, the construction wood would be disassembled and utilized in future construction projects. And thanks to timber’s ability to bind CO2, an equal amount of carbon emissions from the construction phase is expected to be absorbed into the building’s wooden materials, during the first 50 years of its lifetime.

A scalable model

The years of investment in innovation have equipped Urban Partners' teams with specialized expertise in sustainable construction practices. Several elements have been tested and succeeded and are now ready to be deployed elsewhere.

Expanded green financing options will help to underpin the economics of future Urban Partners projects. The knowledge of deploying smart energy systems bringing different solutions together in concert – and particularly the use of geothermal heating – will bring significant operational cost savings across multiple developments.

The model of cooperation and pushing suppliers to bring more sustainable solutions will be critical for further decarbonization with a strong business model, in particular the experience of using wood for almost all the building and supporting the construction using a site cover. Upcycled materials have a contribution to make to both decarbonization and business case, provided they are used in a selective way that is convenient for the project.

With the experience and learnings from Ripple Residence, we further see the evidence that the highest levels of decarbonization can be achieved on strong commercial terms.

Ripple Residence story

Watch the story about Ripple ResidenceRipple Residence

Nordhavn, Copenhagen, Denmark

Urban development, residential property in Nordhavn, Copenhagen, Denmark

13,100 square meters, 115 apartments

Targets EPC A, DGNB Platinum & DGNB Planet certifications

Construction consists of cross-laminated timber

Planned to install heat pumps and rooftop solar PV

Integration of recycled materials from demolished building in Nordhavn

Primary building parts (façade, floor slabs, structure) designed for prefabrication, modularity, and future disassembly/re-use

Expected completion in 2024-2026